Recently a friend sent me a link to KR4LO's "Air Boss" Antenna Launcher which uses small 2 oz. "egg sinkers" in lieu of tennis balls. The Air Boss looks like a well thought out design with great range, and for the price, an excellent deal.

But I already had a launcher that I'd built. It got me thinking, though...could I modify mine to use the same approach?

Yes, I could. And I did. Here's the new design...

The barrel is now a 3 foot length of 3/4 inch diameter schedule 80 grey plastic pipe (threaded at both ends), cut down to about 30 inches (explained below).

My first iteration used white 3/4" diameter PVC pipe for the barrel (1/2" was too narrow), but its inner diameter was slightly too large -- too much air was escaping around the sides of the 2 oz. egg sinker I was using as a weight, compromising its range. I had to wrap about 7 turns of masking tape around the "waist" of the sinker to bulk it out enough to get a good seal in the pipe (the sinker was still loose inside the barrel, but not too loose).

Compared to the white PVC pipe, the grey pipe has a slightly narrower inner diameter (and it seems stiffer, too -- less likely to bend). So the egg sinker fits into it better, but I still add about 2 turns of masking tape around the waist of the egg sinkers, but this additional bulking-out might not be needed.

The barrel attaches to a 3/4 inch PVC ball valve (threaded, female connections), so, for storage, it's very easy to unscrew the barrel from the air-chamber/valve assembly. Note: my original design used a 1/2 inch ball valve. This meant that I had to adapt the threaded 3/4" threaded pipe to the 1/2" ball valve. Which I did. Unfortunately, during testing I snapped off one of the glue joints near that valve. Rather than rebuild it with the same 1/2" valve, I thought it better to use a valve that could mate directly with the barrel, without adapters.

This new ball valve is a bit stiffer to turn than my original one. I was worried that this meant I couldn't turn it as fast, and therefore the "explosion" of air when I opened it wouldn't be as powerful.

I tried lubricating the ball with "Faucet and Valve" grease, but this didn't seem to have any effect. So I instead jury-rigged a handle-extender with a piece of scrap kindling and a hose clamp:

Not elegant, but it seems to work.

The reel is inexpensive, purchased at Walmart. The reel came with a cheap no-name, no-spec line pre-installed. I removed this line and installed in its place 30 lb. test "Spiderwire" braid (about 125 yards).

The fishing reel is attached to the barrel with a couple of hose clamps.

The fishing weights are 2 oz. egg sinkers (I picked mine up at Walmart). I didn't want the fishing leader to pass on the outside of the sinker, so it runs only inside the sinker, with lead split-shot clamped on the leader at either end to keep the sinker from moving around:

One thing I've learned with antenna launchers, be they sling-shot, pneumatic, or whatever...if you aren't careful, you can get your weight (or tennis ball, etc.) stuck up in a tree. For me, this usually happens when I'm not satisfied with where the shot went -- then I try to pull the line back (with weight still tied to the end of the line) so that I can try again. The weight will start swinging on the end of its line (like a pendulum) as I'm pulling it up through the tree branches, and then suddenly, it's done a loop-de-loop and wrapped itself around a branch! Arrrgh!

This time I wanted to improve the system:

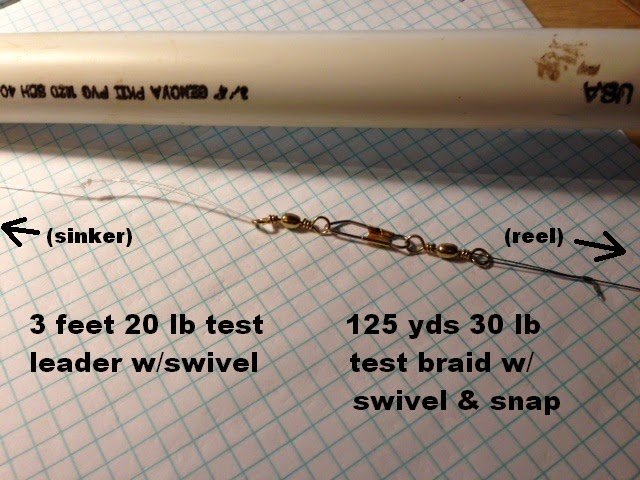

- The weight is attached to a short length of leader (about 3 feet), at the other end of which is attached a barrel-swivel.

- The main line (attached to the reel) has a barrel-swivel with snap at the end to which the leader will attach.

- Prior to making a shot, the leader's barrel-swivel is clipped to the line's snap.

- Then, after the shot has been made but before reeling a line back, simply unsnap and remove the weight and leader. No untying knots!!!

Here's an image of the swivels and snap:

Note: For the sinker's leader I first used some light weight mono-filament line that came with the inexpensive reel I'd purchased. My thinking: because I was using 30 lb. test line for my main line, if my sinker did get stuck in a tree, I wanted something that, if I pulled on it hard, would break before the 30 lb. line broke.

Unfortunately, this unknown line I used as my leader was just a bit too light weight. On my second test shot, it parted and the sinker went sailing over the tree and out of sight.

The red arrow points to where the leader's new end.

Lesson learned. Now I'm using 3' leaders (purchased at Walmart) that are 20 lb. test and have a barrel-swivel at one end and a barrel-swivel-with-snap at the other end. I remove the swivel-with-snap from its end of the leader -- it's on this end that I'll attach the egg sinker. (I can then attach one of these swivel-with-snaps to the end of my main line). Also -- the 3 foot leaders I used come with loops in the line at their 1 foot and 2 foot marks (for attaching other hooks, I suppose). I clip the loops open to prevent them from snagging on branch stubs, etc.

Here's a photo of the leader. If you look closely you can see the two loops before I clipped t hem:

(click on image to enlarge)

Note regarding the leaders: after about two dozen shots into trees, my leader (see the photo above) separated at one of the pre-installed loops -- I'm guessing that the knot used to make a loop weakened the mono-filament and it eventually parted. For this reason, if I build more 2 oz weight leader assemblies, I'll probably just use 3 feet of the 30 lb Spider braid (that I use on my reel) in lieu of the mono-filament.

For better visibility, I spray painted the weights fluorescent orange:

Hot chile peppers in the blistering sun...

(with apologies to Dylan)

If I'm unsatisfied with the shot and decide to reel back the line for another go, I first unsnap and remove the leader and its weight and then I attach a short length of Flagging-Tape to the snap (this could be a short length of rope or string, too -- just something to add some weight to the end of the line). This acts as a bit of drag on the end and helps keep the snap-end of the line from flopping around and possibly wrapping around something as I'm reeling it back in. (That's my theory, at least.)

Other notes:

- Always close the snap before reeling the line back!

- The grey 3/4" barrel was cut down from its length of 3 feet to about 30 inches so that, when the sinker has dropped down inside the barrel all the way to the barrel's bottom (make sure the valve is closed, or you'll drop through to the air chamber!), the swivel on the leader is just outside the barrel, not in the barrel.

- Useful knots: Double-surgeon's loop knot (great for attaching swivels or making slip-knots), and the uni-uni knot (for splicing line together, which I discovered I needed to do when my more-than-200-feet of line on the reel (which I thought would be adequate) came up short in one of my shots over a very tall tree. I'm now using the entire 125 yards of the purchased Spiderwire.)

But how high can I get it? The tree in the photo below is significantly higher than the one in the photo above. With 50 psi of pressure, maximum height that I can achieve seems to be on the order of 90 - 100 feet, per this photo (after shooting the weight over the branches, I reeled up the flagging-tape "tail" until it seemed about at its max height). Note that the measurement below doesn't take into account perspective, so actual height could easily be over 100 feet:

(click on image to enlarge)

Much better than my tennis-ball antenna launcher, but can height be improved? I'm hopeful, but nothing I've tried has yet made a significant difference.

Standard Caveats:

Use at your own risk. If you build one of these, don't overstress the PVC by pumping in too much air (I usually pump it up to about 40-50 psi). Also, follow the instructions with the PVC glue, and, after handling the lead sinker and split shot, I'd recommend washing your hands.

Plus, when the weight descends, it has a lot of energy. It has buried itself a good half-inch into the back lawn here -- I almost thought I'd lost it, then ran into the fishing line leading down into a hole in the ground. So when you're aiming, pay attention to where it could fall!

All of which is to say: use common sense!

And, as always, I might have made a mistake in my equations, assumptions, drawings, or interpretations. If you see anything you believe to be in error or if anything is confusing, please feel free to contact me or comment below.

And so I should add -- this design and any associated information is distributed in the hope that it will be useful, but WITHOUT ANY WARRANTY; without even the implied warranty of MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE.