The ME-165/G is a military SWR and Power meter, designed for the HF

bands (1.5 - 30 MHz), that includes an internal 600 watt dummy load.

The

image, below, shows the ME-165/G as part of the AN/GRC-26D shelter-mounted

radio teletype station:

The unit provides a convenient way to switch the dummy load in and out

of the transmission line, plus, if tuning an antenna tuner in SWR mode, its

SWR circuitry allows the transmitter to always see a 50 ohm load, irrespective

of the actual load at the unit's Output port. So you don't need to worry

about destroying your finals if you make a mistake while tuning your antenna

tuner.

There are four modes of operation (per the four positions of

the front panel's rotary switch). The table below describes how the

ports connect and the meter function for each of these four modes:

The following illustration shows this same information as a "functional

diagram" (i.e. part block diagram, part schematic).

Antenna Tuning Procedure:

When tuning an antenna tuner, the ME-165/G should first be placed

into "ADJUST" mode and the "ADJUST" potentiometer rotated for a full-scale

meter reading while transmitting a CW signal.

Then turn the rotary

switch to its "SWR" position and adjust an external antenna tuner (connected

between the ME165/G's Output connector and the antenna) to give a minimum

reading on the SWR meter (for a correctly tuned tuner, the meter's needle

should end up in the green-region at the left-hand side of the scale).

Here

is a closeup of the Power and SWR meter scales:

Note that the SWR scale is NOT accurate above about 2:1. (I'll

discuss this in more detail later in this blog post).

Schematic:

The schematic, from the Army's Technical Manual. I've corrected a couple of errors (my corrections are in

red):

Also, note that C8 (the capacitor at the Input connector) is listed in

the schematic as 40 pF. In the two ME-165/G units that I have, its

capacitance is actually 39 pF.

Schematic Notes:

1. The 1200 ohm, 25 watt resistor, R15 in the schematic, in

series with the SWR Bridge circuit reduces the power delivered to the SWR

bridge circuit (therefore, the bridge can use 1/2 watt resistors).

2.

SWR Detection is via a Wheatstone bridge. The bridge is balanced when

the load at the ME-165/G's Output port is 51 ohms.

3. C6 puts

the ADJUST pot wiper at RF Ground, thus R22 (1200 ohm) is essentially in

parallel with the lower-right-hand side side of the bridge (via

C5) -- i.e. this resistance is in parallel with whatever load

is attached to the unit's Output port.

Thus, an equivalent

resistance (R20, 1200 ohms) must be connected in parallel with the

lower-left-hand arm of the bridge to ensure that the bridge is balanced

when the external antenna impedance connected at the Output side of the bridge

is 51 ohms, resistive.

ME-165/G Performance:

I own three ME-165/G's. Let's look at their performance.

First,

the unit manufactured by Radalab, Inc:

The (first) Radalab, Inc., ME-165/G (circa 1970's):

I picked up this unit many years ago. The unit was in good

shape, but a previous owner had replaced the original N connectors with SO-239

connectors.

Inside, the majority of the components are wired point-to-point using

solder posts:

Below is a photo showing the wiring from one side of the Dummy Load to

the rotary switch and from the other side of the Dummy Load to ground.

Note that the load's ground wire goes to C8's ground terminal. This

terminal is then grounded to the front panel via a separate wire.

The

other wire from the load (to the rotary switch) is bound tightly with the

ground wire from the load, using three cable ties.

The 50 ohm, 600 watt load consists of twelve Dale 600 ohm, 50 watt

resistors in parallel:

S-Parameters:

Measuring the unit's S-Parameters

in dummy-load mode with an HP 8753C Network Analyzer:

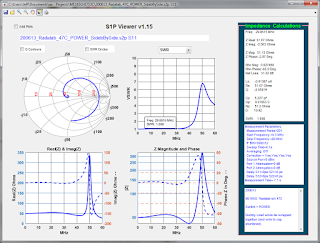

Below is the capture of S11 when the ME-165/G's rotary switch is set to

POWER (i.e. the Input port is connected to the 50 ohm Dummy Load). You

can see that the SWR in the HF band (to 30 MHz) looks very good (1.1:1 at 30

MHz). Not so good at 6 meters, but this load is not spec'd to that

frequency.

When the front-panel rotary switch is in the OPERATE position, the dummy

load is disconnected from the Input connector and the Input is connected

directly to the Output connector.

How does the Radalab ME-165/G

affect performance when it is in its OPERATE mode? Again, let's look at

the s-parameter measurements...

As you can see in the plot below,

there is some insertion loss that worsens with frequency, but this loss is

only about 0.09 dB, worst case, at 30 MHz.

And the SWR of the "ideal" 50 ohm external load, rather than being 1:1,

is now changed by the Radalab ME-165/G to be 1.2:1 (at 30 MHz).

So, some minor adverse effects, but overall, not bad!

Improving the performance of this (first) Radalab ME-165/G in OPERATE

mode:

I had noticed a difference between the Oneida's output wiring and

the wiring of the Radalab unit, and I wondered if this difference accounted

for the slightly worse Radalab Insertion Loss when in OPERATE mode.

The

wiring from the rotary switch to the Oneida unit's output connector had been

routed next to the front panel. But the same wire in the Radalab unit

was routed high in the air, as shown below:

Would moving this output wire to be closer to the front panel make a

difference? Here's a photo of the new routing:

And below is the measured s-parameters for this new routing. Note

that Insertion loss has decreased from 0.09 dB to about 0.07 dB. Note

much of a change, but it's in the right direction.

And the image below shows that the SWR of the "ideal" 50 ohm load is now

1.1:1 (from 1.2:1). Again, a slight improvement, but an improvement

never-the-less.

Oneida Electronics Inc ME-165/G (circa 1963):

My second ME-165/G was manufactured by Oneida Electronics Inc,

around 1963 (per the suffix on the Order Number listed on the front panel

tag).

This unit still has the stock N-connectors on the front panel

(note that in the image, below, there are BNC adapters attached).

Here's a look at the inside terminal-board used for wiring the

components. You can see that it is similar to the later Radalab's board

(shown above):

But there is one noticeable difference between the Radalab board and the

Oneida board, which is the use of clips to hold in CR1 and CR2, rather than

soldering them to posts, as shown in the two photos, below:

I imagine clips allowed easy replacement of the original 1N69A diodes in

case they blew out. Note that CR2 (a 1N277 diode) has its leads wrapped

around the clip's posts. This diode probably replaced a bad 1N69A

diode.

The image below shows Oneida's wiring from the 600 watt

dummy load to the rotary switch and ground. Note the difference between

this wiring and the wiring in my Radalab unit (shown earlier in this

post). The wires below are not routed together in

parallel, and the dummy load's ground wire goes directly to a ground terminal

on the front panel, rather than first routing to C8's ground.

Also, the dummy load's resistors are not Dale resistors; instead they

are TRU-OHM 600 ohm non-inductive resistors:

Improving the performance of the Oneida ME-165/G:

When I first measured the SWR of the dummy load, I noticed that

it rose to 1.5:1 at 30 MHz. So I tried to improve its SWR by changing

the dummy load's wiring to look exactly like the wiring in my Radalab

ME-165/G.

But with this modification the SWR rose to 1.75:1

at 30 MHz (see below). Yikes -- my attempt to make the Oneida's wiring

match the Radalab wiring moved SWR in the wrong direction!

OK -- mimicking the Radalab's wiring was not going to work.

Playing around with the separation of the dummy load's two wires, I discovered

that (a) separating the two wires far apart, and (b) keeping the

original ground wire to the dummy load, in addition to the new (red)

ground wire I'd added, improved the SWR.

The image below shows the

new dummy-load wiring. The red wires are 14 AWG THHN stranded wires

(insulation rated to 600V). Note their separation! You can see the dummy

load's grounding red wire goes to C8, just like the wiring in the Radalab

unit. But you can also see that the original ground wire is still

connected to the dummy load (and now routed a bit closer to the upright

mounting plate).

And here is the new SWR measurement. Now it is 1.2:1 at 30 MHz.

(Perhaps the difference in wiring is due to a difference in impedance

between the Oneida's 600 ohm TRU-OHM resistors and the Dale 600 ohm resistors

in the Radalab unit?)

In OPERATE mode the Oneida unit's

measurements look very good. Here's S21. Insertion loss is only

about 0.04 dB at 30 MHz.

And there is little impact on the SWR of an external 50 ohm load.

As you can see, below, the SWR at 30 MHz for the external 50 ohm load is

1.09:1.

Second Radalab, Inc., ME-165/G (S/N 47C):

The first Radalab unit I discussed (above) is serial number

7C. This second ME-165/G is serial number 47C.

Interestingly,

its component-mounting board no longer has the clips for the diode

leads. Instead, all components are attached with soldering posts:

(This difference could be due to a later unit upgrade, or it might have

been a change during the manufacturing run).

Otherwise, the two

Radalab units look very similar.

S-Parameters:

Again, made with my HP 8753C Vector Network Analyzer.

Below

is the S11 plot with the Function Switch set to POWER. Note that the SWR

at 30 MHz is about 1.5:1. Not as good as I would like it to be.

Below are the s-parameters with the Function Switch set to OPERATE:

SWR (of an external 50 ohm load) is transformed to about 1.3:1 (from the

load's original 1:1) at 30 MHz.

And Insertion Loss is about 0.1

dB.

Improving the performance of this second Radalab ME-165/G:

The image below shows the original wiring of this ME-165/G:

If I routed the dummy-load wires together (using tie-wraps), SWR in

POWER mode improved.

The image below shows the new routing of the

two dummy-load wires:

(Note, I had to trim off a small amount of the wire going to the big

black cap because it was just a too long, as you can see in the photo,

below.)

With this modification, the dummy-load's SWR went from 1.5:1 to less

than 1.1:1 (see below).

I had noted that the wire to the output jack was up in the air. So

I moved it to route along the inside of the front panel.

I don't

know the voltage rating of this wire's insulation, and I was a concerned that

it now ran against the grounded metal of the front panel, so to prevent the

possibility of arcing I added a bit of Kapton tape between it and the panel

for extra voltage insulation (and I added a second piece of tape to hold the

wire next to the panel), as shown below:

This modification improved OPERATE mode's Insertion Loss (from 0.1 dB to

about 0.05 dB) and the "through" SWR of an external 50 ohm load (now 1.1:1

from the unmodified version's 1.3:1).

An SWR Meter that does not measure SWR:

While using the ME-165/G, I discovered that its SWR

readings can be very inaccurate'

Here's a look at the SWR scale on

the ME-165/G meter.

As I mentioned, the SWR reading can sometimes by quite inaccurate.

For example, what should be the SWR when the load is a short? Of course,

it should be infinite (meter needle at full scale). But

that's not what the ME-165/G shows:

So my Radalab unit shows that the SWR of a short-circuit is somewhere

between 3:1 and 4:1. And if I repeat the test on my Oneida unit, the SWR

of a short measures slightly less than 3:1 (the difference between the two is

probably due to drift of component values over time).

In other

words, both of my ME165/G SWR meters show an SWR of around 3:1 for a short

circuit. Neither unit shows the correct SWR of infinity

(meter needle at full scale).

Despite this gross SWR inaccuracy for

a short-circuit load, the SWR meter's accuracy seems to improve considerably

below an SWR of about 2:1. Therefore, as long as the goal is

to tune the antenna for minimum SWR, rather

than measure its SWR value, the ME-165/G does the job quite

well.

But I still wanted to know -- why was the SWR meter so

inaccurate for a short-circuit load?

SPICE Simulations:

I decided to do some SPICE simulations to get a better

understanding of what to expect from the ME-165/G SWR detector.

The

ME-165/G's SWR measurement circuit is based upon a simple Wheatstone Bridge,

with the unknown load to be measured represented by the lower right-hand arm

of the bridge, as shown, below:

In an ideal Wheatstone Bridge we can take the difference between Va and

Vb, then divide by Va, and then take the magnitude of this

value, we can create a set of numbers that we can equate to SWR values, as

shown in the table, below:

Note that the quantity |(Va - Vb)/Va| is equivalent to the magnitude of

the load's Gamma:

In other words, if we could measure Va and Vb with high impedance measuring

circuits (so that there are no unwanted currents through either arm of the

bridge that might alter the bridge's balance) and then perform the math, we'd

get a number equal to the magnitude of the load's Gamma, and thus translatable

to its SWR.

Sounds straightforward, but note...the equation

requires a division by Va. Is there an easy way to accomplish this

division with simple circuitry?

If we could adjust our voltages so

that Va equals 1 (while keeping the ratio of Va to Vb constant), then we can

skip the division step, because we would be dividing by 1.

In the

bridge circuit above, for example, maybe we would have a switch that we would

first set to an "Adjust" position, connecting a high-impedance meter to Va and

letting us scale its gain (via a potentiometer) until the meter's needle is at

Full Scale, i.e. so that Va now equals 1.

And then we would flip

the switch to measure |Va - Vb|, using the same gain-adjusted high-impedance

meter, to give us a direct reading of Gamma thus SWR (e.g. a meter

reading of 1/2 Full Scale would equal a Gamma of 0.5, or an SWR of 3:1).

But

we can see from the SWR scale on the ME-165/G meter, and from our example

measuring the SWR of a 0 ohm load, that the ME-165/G is doing something very

different -- something that affects the accuracy of its SWR readings.

The

problem is that, for the equation Vswr = |(Va-Vb)/Va| to give accurate

results, Va must be measured while Rload is connected to the

Wheatstone Bridge. This is because, given the ME-165's circuitry to limit the

power to the Wheatstone Bridge (i.e. the series 1200 ohm, 25 watt resistor ),

any change in Rload will affect the voltage at node Vc at the top of the

bridge (because a change in Rload will change the current through that arm of

the bridge, and thus it changes the current (and subsequent voltage drop)

through this series 1200 ohm resistor feeding the bridge).

Because

we are adjusting Va to be 1 (to avoid a mathematical division), the value of

Va that was set during the "Adjust" step should (ideally) be the same as the

value of Va used during the SWR measurement step.

But in the

ME-165/G, these two Va's are not the same. The Va of

the Adjust step is measured without Rload connected to the

bridge, while Va of the SWR measurement step is

measured with Rload connected to the bridge.

So Vc

will be different for these two steps, and thus Va (which equals Vc/2) will

also be different.

Let Va1 be the value of Va measured during the

Adjust, and "Va2" be the value of Va measured during the SWR measurement

step. Because the "Adjust" step is, essentially, determining the value

of Va that we will use to normalize the quantity (Va2 - Vb), the original

equation |(Va - Vb)/Va| becomes:

Vswr = | (Va2 - Vb) /

Va1 |

I can simulate the result in LTSpice by adding another arm to

represent the "unloaded" Va (i.e. Va1). Below is the model, and I've

annotated it with the simulation results of this new equation.

We can see that the measured SWR values are different

for loads with the same actual SWR (e.g. 0.34 for 150 ohms

versus 0.21 16.67 ohms -- both loads have an actual SWR of

3:1), and it explains why the ME165/G's measured SWR of a short is so far off

from what it should be.

Let's now add the diode detector and

meter circuit to the simulation and see how they affect performance.

Please note:

1. LTSpice doesn't seem to have any Germanium diode models, so I'm using a Schottky diode (1N5817), instead. (Note: if replacing the original CR1 or CR2, I'd recommend using a 1N5818 or 1N5819 for their higher peak-reverse-voltage specifications.)

2. I've adjusted the amplitude of the driving voltage source so that R23 (representing the "Adjust" potentiometer) is 0 ohms and the meter current is 1.0 mA when Rload = 1 Megohm (by setting the current equal to 1 mA for Rload = 1 Meg, I am effectively mimicking the "Adjust" step of the SWR measurement).

3. The 1 mA meter is represented by Rmeter (58 ohms), per my measurement of the meter's resistance. And I've increased the meter's bypass cap (C7) from 1 nF to 100 nF to knock down the RF across the meter and make it easier to determine the DC current passing through Rmeter.

4. The frequency of the sine-wave drive is 4 MHz.

5. Circuit parasitic elements are not included in the simulation.

I would expect the addition of the diode-detector to throw off the simulated

values determined earlier (for the "ideal" Wheatstone Bridge), because the

diode will conduct during part of the RF cycle, squirting current from the

right arm of the Wheatstone Bridge (Vb) into the left arm (Va) and thus

changing these two voltages.

Here's the new LTSpice schematic:

And below are some simulations of this new circuit...

First,

verifying that the "meter" current is 1 mA when mimicking the ME-165/G in

ADJUST mode, i.e. when there is no load (Rload = 1 Megohm):

Next, replacing the "open" load with a short. Ideally, the current

should remain 1 mA (representing an infinite SWR). But as you can see,

the DC current is 0.4 amps, which is quite a ways off from the 1 mA target.

Let's take a look at two loads that should each have an SWR of 3:1:

First,

a Load = 150 ohms (note that the meter current is 0.32 mA):

Next, a Load = 16.67 ohms (note that the meter current is 0.21 mA):

These results are not exactly the same as the results made without the

actual diode-detector in the circuit, but they are close. (I believe the

difference is due to the actual diode-detector acting as a current path

between the two arms of the bridge, when in fact these two arms should be

isolated from each other).

Below is a table of simulation results,

simulated at 4 MHz and at 10 MHz, for different load resistances. The

third column is the actual DC current required to drive the meter's needle to

the appropriate "tick" mark on the ME-165/G meter's SWR scale. If you

compare the "required" current to the "actual" (i.e. simulation) current, you

can see that only some of the simulated currents come close to target

values. Only when the load's actual SWR is about 2:1 or better do we

seem to get in the ballpark of the actual meter tick marks, irrespective of

whether the load is greater than 50 ohms, or less than 50 ohms.

The simulated results also depend upon the type of diode

used. As I mentioned earlier, LTSpice does not seem to have a Germanium

diode model, so I used a 1N5817 Schottky diode instead.

I thought

I'd look at the simulation results using other LTSpice diode models. The

table below shows simulation results of two different Schottky diodes (1N5817

and BAT54), and a common 1N4148 Silicon diode.

Note the loss of resolution at low SWRs if using the 1N4148 diode.

This will result in tuning appearing to give a 1:1 SWR over a broader range of

loads, which is not desired!

Conclusions:

1. The ME-165/G provides a 600 watt dummy-load and

power-measurement meter for the HF range of 1 to 30 MHz) that can be easily

switched in and out of the transmission line.

2. It might be

possible to improve either the dummy-load's SWR or the "through" insertion

loss at the high end of the HF range by changing wire routing. Use a

Vector Network Analyzer (such as the NanoVNA) to accomplish this by measuring S21 and S11.

3. The

ME-165/G provides an SWR measurement mode useful for adjusting antenna

tuners. However, the meter's accuracy very much depends upon the load

value. Accuracy seems to improve as the SWR drops below 2:1.

4.

If replacing diode CR2 in the SWR circuit and you cannot find the original

1N69A (or 1N277), try using a Schottky diode such as a 1N5818 or 1N5819,

rather than a generic silicon diode such as the 1N4148. (On the other

hand, a 1N4148 diode should be fine as a substitution for CR1).

I

recommend the 1N5818 or 1N5819 instead of the 1N5817 I used in my simulations

because these two diodes have a higher peak-reverse-voltage specification

compared to the 1N5817. Although PRV of the 1N5817 is 20 volts and the

worst-case simulated peak-reverse-voltage was around 14 volts (for Vin =

250Vpp, F = 2 MHz, Rload = Open, and the bridge resistors assuming a worst

case 10% variation (R19 = 56 ohms, R21 = 46 ohms, and R18 = 46 ohms)), I

personally would prefer to have a bit more PRV margin.

Resources:

Technical Manual TM 11-6625-333-15

PA0FRI ME-165/G website

Standard Caveat:

I might have made a mistake in my designs, schematics, equations,

models, etc. If anything looks confusing or wrong to you, please feel

free to leave a comment or send me an email.

Also, I will note:

This

design and any associated information is distributed in the hope that it will

be useful, but WITHOUT ANY WARRANTY; without an implied warranty of

MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE.

3 comments:

thanks for this, everything you showed also worked in mine.

One question: I have plenty of 1N5818, can I replace both CR1-CR2 with them ?

73 de Peter

Hi Peter,

The 1N5818 should be fine.

Best regrds,

- Jeff

thanks Jeff.

Yours is the best ham radio blog on

the internets. I’ve also fixed a Cheyenne

thanks to you.

Peter

Post a Comment